Product Design & Development

Innovating Ideas into Reality

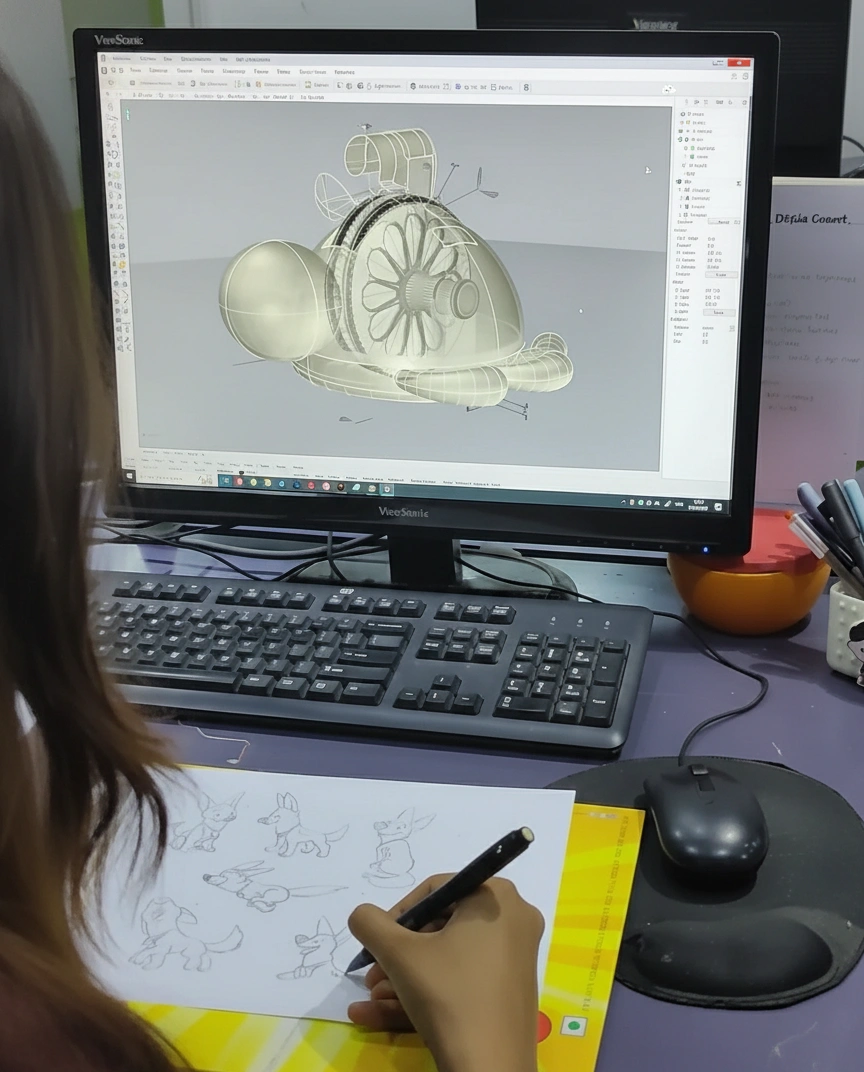

At Pramara, product innovation begins with a simple idea — and evolves into a tangible, market-ready product through creative design and precise engineering. Our design and development team is the driving force behind every product that carries the Pramara name. From brainstorming concepts to delivering functional prototypes, we blend creativity, technology, and manufacturing intelligence to deliver excellence at every stage.

We understand that in today’s competitive world, a product must not only look great but also be efficient, durable, and cost-effective. That’s why our experts focus on design thinking — ensuring each concept aligns with both brand goals and end-user expectations.

Advanced Design & Engineering Capabilities

- In-house design studio equipped with advanced CAD/CAM tools for precise design development

- 3D modeling and digital simulations used to visualize product concepts before prototyping

- Rapid prototyping capabilities enabling faster validation and refinement of ideas

- Skilled engineering team ensuring accurate mold development and manufacturability

- Expertise across toys, promotional products, OEM items, and custom gifting solutions

- Strong focus on dimensional accuracy and consistent product performance

- Seamless translation of design concepts into production-ready engineering outputs

- Value engineering applied to optimize material usage and reduce production costs

- Designs created to be aesthetically strong, functional, and scalable for mass manufacturing

From Concept to Creation — We Make Brands Talk

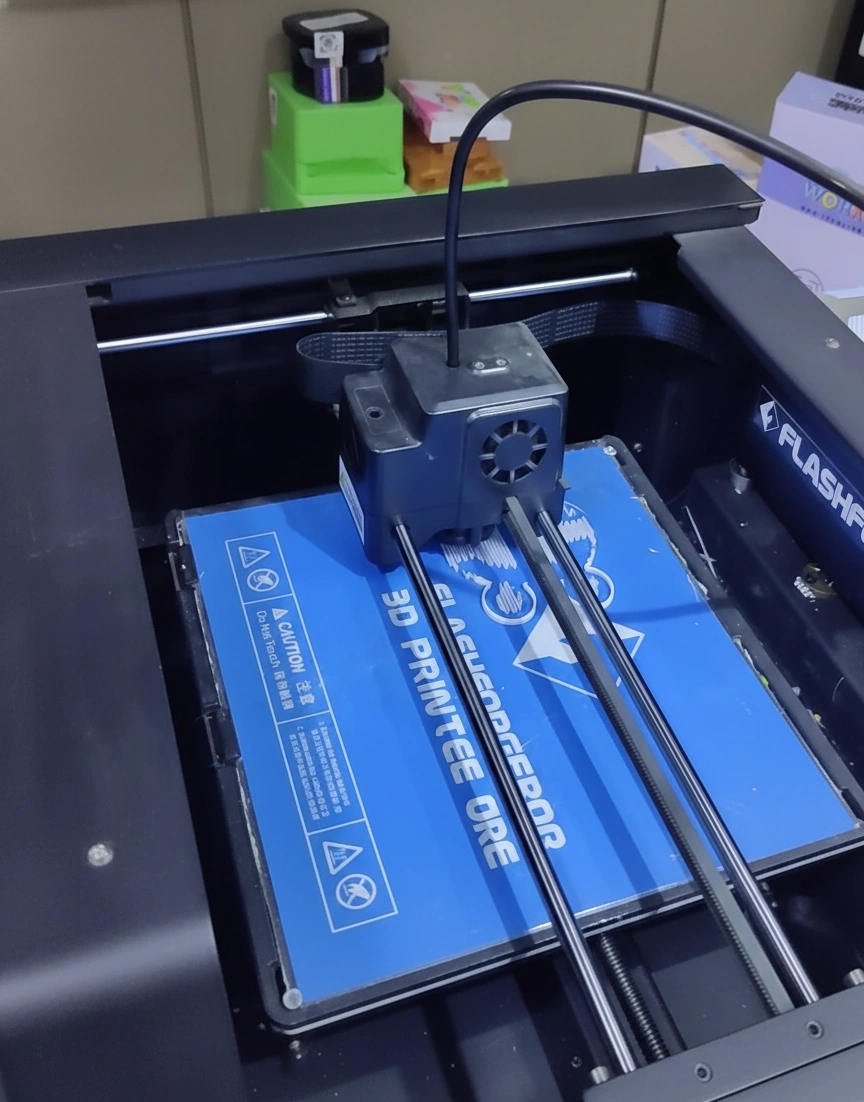

Rapid Prototyping & Sampling

- Ability to quickly convert digital concepts into accurate physical prototypes

- Use of 3D modelling and prototyping tools to validate form, fit, and function

- Fast sampling process that helps shorten development timelines

- Prototypes evaluated for aesthetics, ergonomics, durability, and safety compliance

- Smooth design-to-sample workflow ensuring minimal errors and improved precision

- Enables clients to review and refine products before final mould development and mass production

From Concept to Commercialization

- Seamless transition from design to tooling and manufacturing through an integrated, in-house development ecosystem

- Complete quality control and confidentiality maintained at every stage of the product lifecycle

- Designs engineered for accuracy, manufacturability, and large-scale production efficiency

- Use of advanced design software and skilled technical teams to ensure superior outcomes

- Products developed to meet industry standards in innovation, sustainability, and performance

Key Highlights:

- In-house product design and engineering expertise

- CAD/CAM-based 3D modelling and digital mould development

- Rapid prototyping for quick sample creation

- Streamlined design-to-production workflow

- Faster turnaround with complete control under one roof